- 1.High breaking ratio and low operational cost. The unique design of the rotor provides a perfect combination of the abrasive material with the crusher equipment, offering high breaking ration and low parts’ wear.

- Low consumption of wear parts. VSl series crushers adopt an optimum impact angle for the crushing chamber to minimizefriction on the wear parts, thus reducing the operational cost by 30%.

- High output and yielding capacity. Through optimization design, the structure is made more compact with the use of a singledriving shaft. This generates greater capacity and gains better crushing ratio through less crushing steps.

- Excellent particle sizes. All aggregates appear in cube shape, and are especialy suitable for processing artificial sand and foraggregates shaping.

- Flexible applications. This series of crusher is buit with various types of confiqurations to meet the reguirements of diferentapplication conditions. Applications range from low abrasive materials to high abrasive materials.

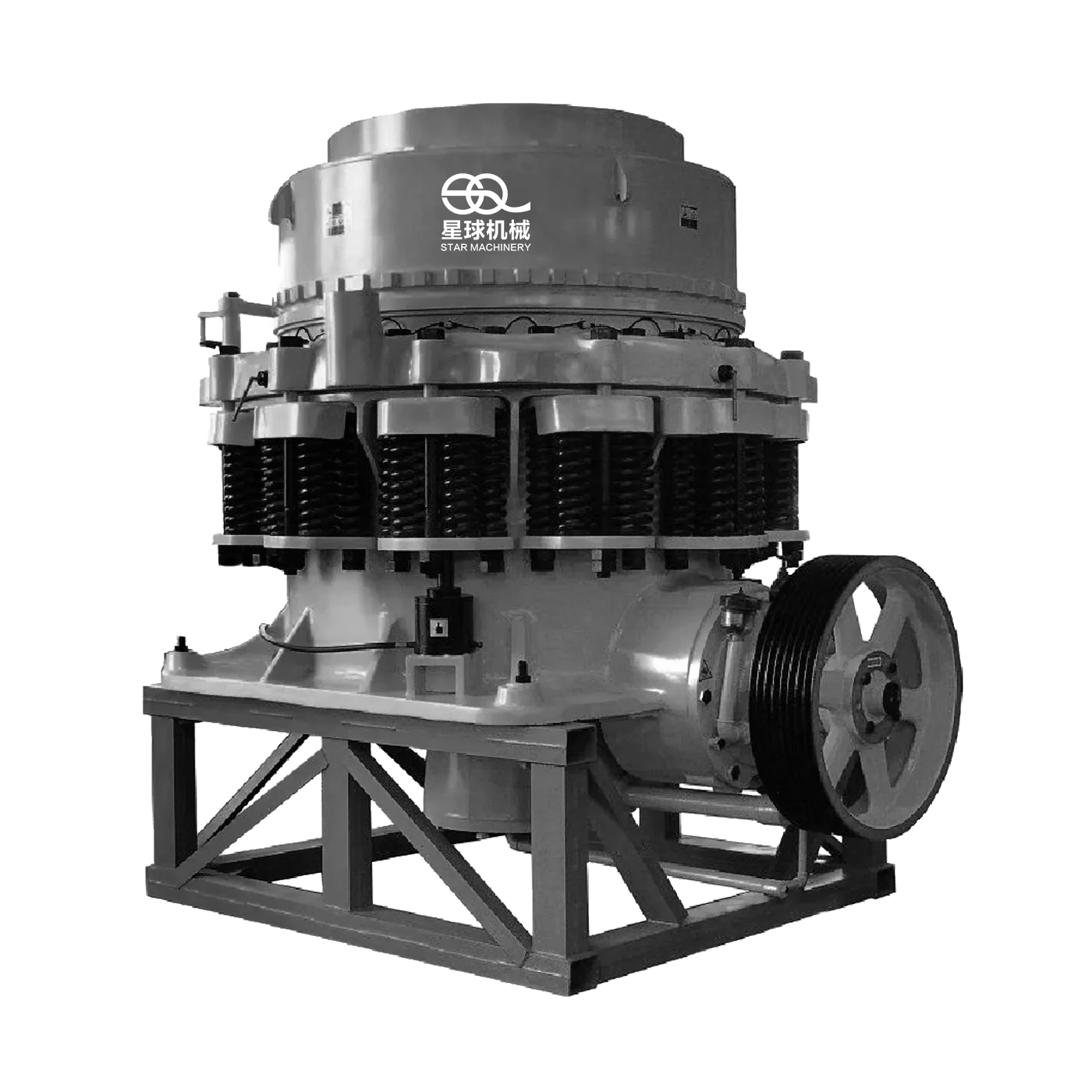

- Integrated hydraulic control and bearing lubrication. The hydraulic control box is a standard configuraion for the entire seriesof crusher. it has a dual function to regulate the feed opening and to adjust the motor seat to control the tension of the conveyingbelt. All operations are carried out with a manual pump. The semi-automatic lubricating system is completely sealed to avoiddust and ensure the sufficient lubrication of the bearing.

PE/PEX Jaw Crusher

The jaw crusher is mainly used for breaking rocks of high and medium hardness and with a maximum compressive strength of 320Mpa. PE Series is used in the primary crushing, while PEX series the secondary crushing and fine crushing.